Choosing the right bespoke packaging services is about more than just getting a box made. It’s about design accuracy, cost control, brand presentation, and a smooth process from idea to delivery.

For UK businesses, especially those scaling in e-commerce, food, retail, or manufacturing, bespoke packaging can reduce shipping costs, protect products better, and strengthen brand perception. This guide explains what bespoke packaging services include, how the process works step by step, and how UPAC manages everything under one roof.

What Are Bespoke Packaging Services?

Bespoke packaging services involve the custom design and manufacture of packaging tailored to your exact product, brand, and logistics needs.

Instead of choosing off-the-shelf boxes, bespoke packaging is created to match:

- Your product dimensions

- Your branding and print requirements

- Your protection and sustainability goals

- Your budget and order volumes

At UPAC, bespoke packaging is handled as a complete service, not just a print job.

What’s Included in Bespoke Packaging Services?

1. Design & Structural Planning

The process starts with understanding:

- Product size, weight, and fragility

- How the product is packed, shipped, and stored

- Branding requirements and unboxing experience

This ensures the box is structurally sound and cost-efficient, not oversized or over-engineered.

2. Prototyping & Sampling

Before full production, prototypes or samples can be created to:

- Test fit and protection

- Check folding, closure, and stacking

- Review print placement and finishes

This step reduces costly mistakes during bulk manufacturing.

3. Printing & Branding

Bespoke packaging allows full control over how your brand appears:

- Logo placement

- Colour accuracy

- Internal and external print

- White-top board for sharper, more vibrant colours

UPAC supports both simple one-colour branding and complex multi-colour designs.

4. Manufacture

Once approved, packaging moves into production using:

- High-quality corrugated board

- Consistent material grades

- Repeatable manufacturing standards

This ensures every box performs the same, order after order.

5. Delivery & Ongoing Supply

Finished packaging is delivered directly to your site or warehouse. For repeat customers, UPAC can support:

- Scheduled reorders

- Consistent specifications

- Scalable volumes as your business grows

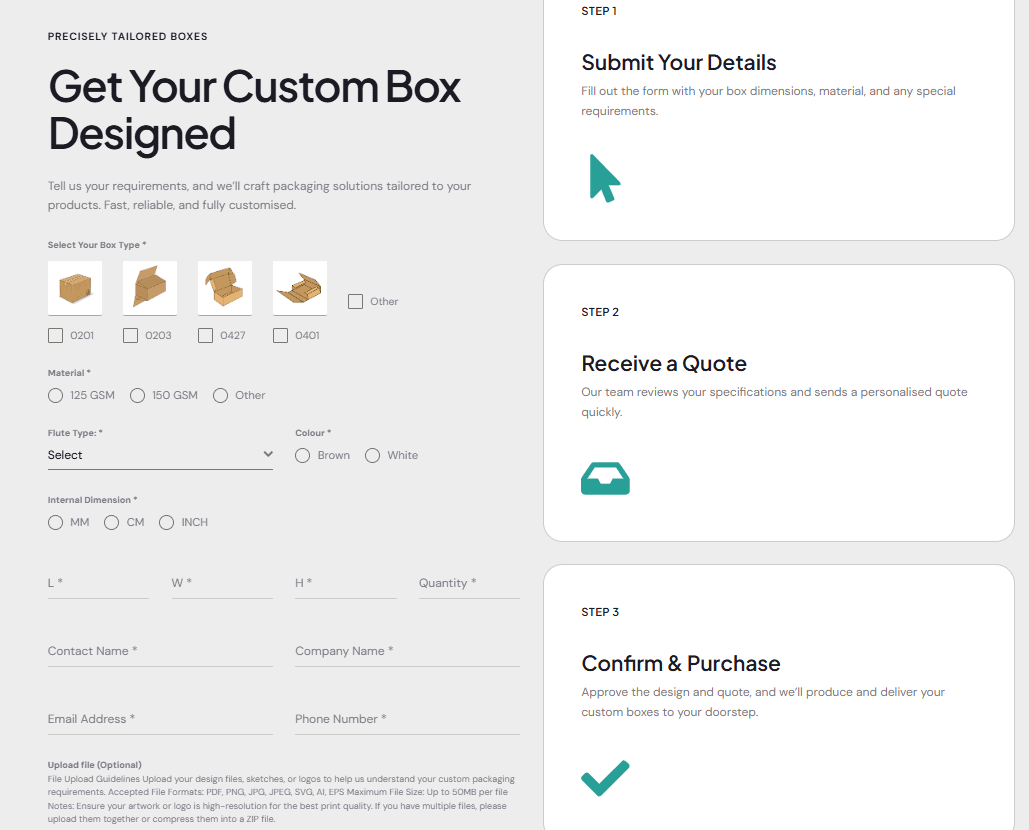

The Fastest Way to Get a Quote: UPAC’s Online Custom Box Builder

The quickest way to start your bespoke packaging project is by using the online Custom Box Builder on UPAC.co.uk. This digital request tool removes guesswork and speeds up quoting.

What You’ll Need to Provide

1. Box Style

Choose a standard box style or FEFCO code, such as:

- 0201 – Standard flap box

- 0427 – Pizza-style or mailer box

2. Dimensions

Provide internal dimensions in:

- mm, cm, or inches

Accuracy here helps avoid wasted space and unnecessary cost.

3. Material & Colour

Options typically include:

- Standard brown board

- White-top board, ideal for premium branding where colours need to stand out

Once submitted, the UPAC team reviews your request and prepares a tailored quote.

Submitting Your Artwork to UPAC

If your packaging includes print, artwork submission is a key step.

Accepted File Formats

- Vector (preferred): AI, EPS, SVG

- Other formats: High-resolution PDF, PNG, JPG

Vector files ensure the sharpest print results at any scale.

File Size

- Upload files up to 50MB directly through the UPAC quote form

Artwork Review & Approval

UPAC’s in-house graphic design team checks every file for printability. This includes:

- Colour setup

- Bleed and margins

- Resolution and alignment

Before production begins, you’ll receive an electronic soft-proof for approval. Nothing goes to print until you’re happy.

If you don’t have print-ready files, UPAC’s designers can assist with artwork preparation.

Lead Times & Approvals

Lead times for bespoke packaging depend on:

- Complexity of design

- Print requirements

- Order volume

Typical stages include:

- Quote & specification confirmation

- Artwork submission and approval

- Production

- Delivery

Clear approvals at each stage keep timelines predictable and avoid delays.

In-House vs Outsourced Bespoke Packaging Services

Many suppliers outsource parts of the process, which can lead to miscommunication and delays.

UPAC’s approach:

- Centralised project management

- In-house design support

- Clear communication from quote to delivery

This streamlined model reduces errors and speeds up turnaround times.

How UPAC Manages the Full Bespoke Packaging Process

UPAC acts as a single packaging partner, handling:

- Consultation and design guidance

- Digital quoting via the Custom Box Builder

- Artwork checks and soft-proofing

- Manufacturing and delivery

This end-to-end service makes bespoke packaging accessible even for businesses ordering custom packaging for the first time.

Final Thoughts

Bespoke packaging services are not just about aesthetics. Done correctly, they improve efficiency, reduce waste, and strengthen your brand at every touchpoint.

If you’re looking for reliable bespoke packaging services in the UK, UPAC offers a fast, transparent, and professionally managed process from concept to completion.

Request bespoke packaging services: Customise Package